Small Part, Big Problem: Preventing Misfires in Shorty Firing Heads

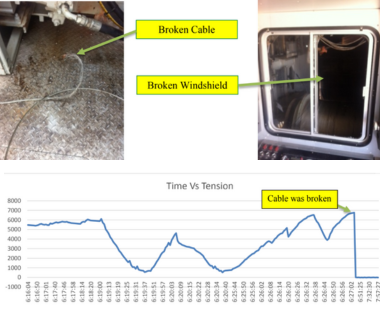

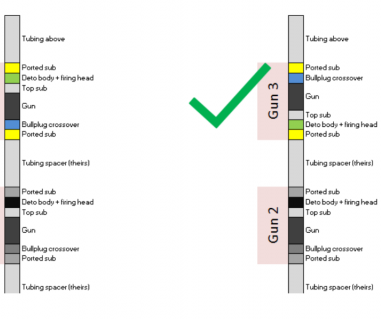

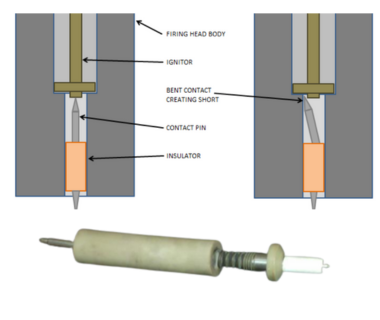

You can prep every sub, torque every joint, and verify every detonator, but sometimes it’s the smallest components that bring everything to a halt. This was one of those jobs—everything ready for plug setting during a wireline and perforating operation. Logging cable was good. Wireline truck dialed in. Pressure control equipment steady. Then came the …